Hon Hai Tech Day & the Future of the Global Economy

[Opinion] How Foxconn's annual showcase encapsulates the seismic changes going on around the world

Good Evening from Taipei,

I wasn’t planning to write about this year’s Hon Hai Technology Day, an annual event since 2020. I figured this incarnation, held on October 8, would be much the same as the last few: all about EVs with some talk about AI. I was wrong.

Let’s start with some Foxconn facts & figures unveiled at the event held in Taipei:

Foxconn holds 40% of the global server-making market

Can provide 80-90% of all the parts for a GB200 server (except CPU/GPU)

900,000 employees across 205 locations in 24 countries

Is building a massive AI-server factory in Mexico, the world’s largest

Operates 10,000 injection molding machines globally

This year the date of the event changed in a significant way. Previously, the showcase for Hon Hai’s vision for the future was held on October 18. That’s the birthday of Terry Gou, founder and former Chairman of Foxconn Technology Group (Hon Hai is the flagship of the group).

In past years, Gou arrived on stage in a Foxconn-built car alongside his successor Liu Yang-wei (aka Young Liu). Last year, although HHTD was still held on his birthday, Gou skipped because he was running for Taiwan’s presidency. Both he and Foxconn needed to keep their distance. Not only was the date changed this year, but Terry Gou was mentioned just once during Liu’s 15min introduction on Tuesday.

Foxconn has moved on from Terry Gou. And Gou, wherever he is, seems to have moved on from Foxconn. That empire, under Gou, grew by leveraging China’s vast, cheap labor force to churn out ever-cheaper electronic gadgets that were shipped from a couple of production hubs to consumers across the globe.

That leads me to explain why this year’s edition of Hon Hai Tech Day was significant not just for the world’s largest electronics manufacturer, but because it explains all that’s changing in the global economy.

Each individual development at Foxconn, and across international trade, is linked to the next as part of a larger theme.

Consumer-Electronics Growth is Fading

Despite accounting for 54% of revenue “Consumer Electronics” didn’t get a mention across two hours of presentations and speeches at this year’s Hon Hai Tech Day. More than half of Hon Hai’s business comes from Apple. The company assembles two-thirds of the world’s iPhones, as well as Macs, iPads, Apple Watch and accessories (it also owns Belkin). Foxconn also does games consoles, smart speakers and e-readers for the likes of Amazon, Google, Nintendo & Sony.

But consumer electronics are the past. (Exhibit A: Apple’s 6% drop in gadget sales last year). Foxconn is desperate to move on.

This year, the Taipei-based company once again pushed its EV business at HHTD. But it added far more clarity to its plans than we saw in the past, and it also put these plans into the context of its broader strategy.

“We’re redefining ourselves with our three intelligent platforms,” Liu told the audience. “It just makes business sense.”

Smart manufacturing — more automation, more flexibility

Smart EVs — boost range, safety, self-driving, fleet management

Smart City — digital health, governance, and citizen services

Foxconn has released a new EV at HHTD each year since 2021, but in doing so has caused a lot of confusion. Its investment in automotive startups like Fisker and Lordstown Motors made people think it was getting into the car business. It’s not. Those investments were a mistake (Foxconn knows that now), and this year various speakers kept reiterating that it’s making reference designs as a showcase of its EV platform ecosystem. Clients can pick and choose which parts of a car they want to buy — from the electronic innards, to chassis, to full body. Or the whole thing, if they really want.

This EV strategy makes sense. There’s more electronics in even a combustion-engine car than all other household gadgets combined, and Foxconn is a master of the minutiae like connectors, wiring, controller modules, and the mechanical pieces which hold it all together.

But I think the company is at grave risk of screwing up if it keeps rolling out completed cars, as though it expects some incumbent or startup to just rebadge a Foxconn model with their own name. Its mixed messaging is painful to watch.

Instead, it should spend more time showing off the guts of a car, explaining why these little pieces are so difficult to master, and how Foxconn is in the best position to reliably supply them. The company did this with computer parts in the 1990s, setting Foxconn up for 30 years of dominance in PC and electronic components. It was this mastery of minutiae that subsequently landed Foxconn the coveted gig to assemble iPhones, a role it’s dominated ever since, yet it never tried to design an iPhone let alone offer Apple a chance to rebadge its own version.

That said, the long-term potential of EVs is undeniable and is part of another important theme:

New Tech Devices are Big & Expensive

The iPhone 16 costs around $1,000 apiece. That’s less than 0.03% the price of Nvidia’s GB200 servers, which Foxconn also makes. It also dominates the broader server business (note Fact 1, above), which enjoys high barriers to entry. Admittedly, far fewer GB200 servers will get shipped than iPhones, but the profit margins are ridiculously fat.

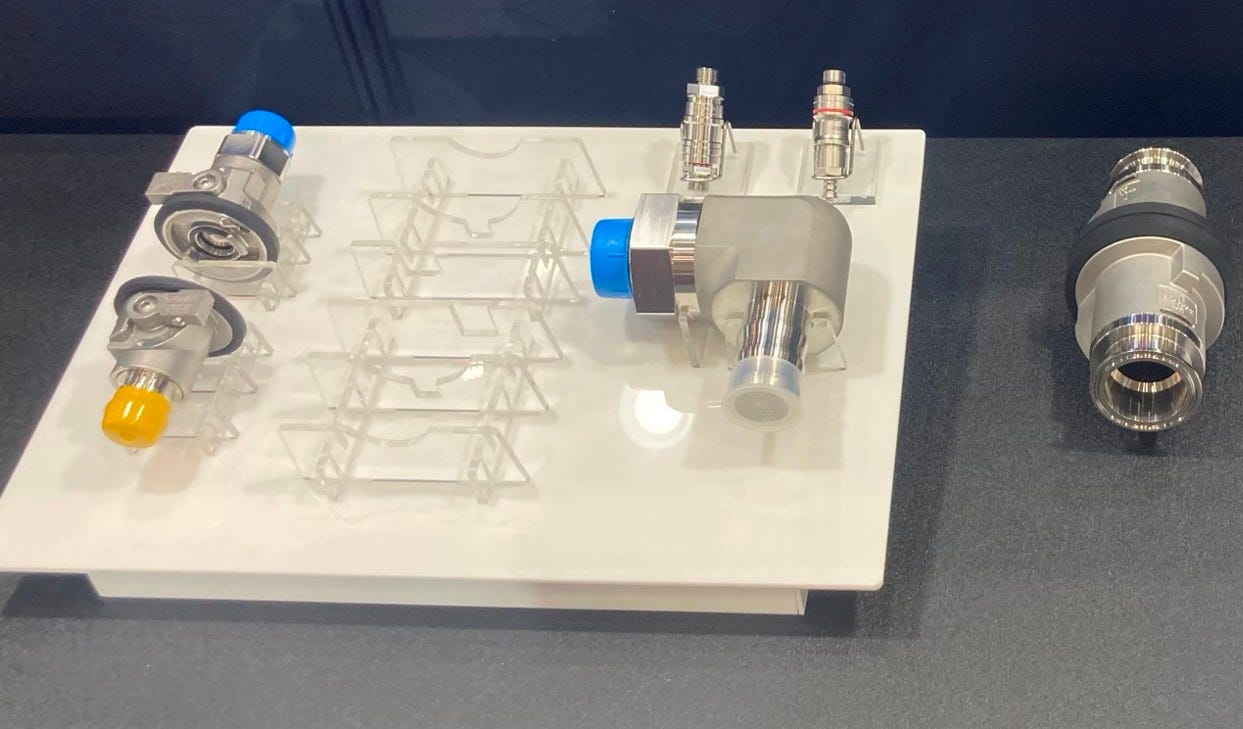

Note Fact 2: Foxconn’s catalog of parts covers up to 90% of what’s required for a GB200 server (beyond the core processors — which TSMC makes for Nvidia 100 miles away in Taiwan). For example, a set of Quick Disconnect hose attachments used for the cooling system — like the metal parts shown in the photo below — run at $3,000 to $5,000 per server (and they’re crazy heavy). There’s more than two dozen individually-machined parts in those larger pieces (far right), and they’re made at Hon Hai affiliates FII and FIT.

Each server weighs around 1,500kg and costs $3.5 million to $4 million. I don’t have the exact figures, but if you imagine the gross margin for Foxconn to make an AI server is double that of an iPhone (I actually believe it’s more), then it can bring in 8,000-times more profit per unit than an iPhone16. Again, volume is much, much lower, but the point is the economics of production (not economies of scale). After they’re assembled in Taoyuan, those servers will be crated up and flown to US datacenters run by Microsoft, Oracle, AWS and Meta.

EVs are the other major member of the Big & Expensive tech category. Sure, they’re only $30,000 to $100,000 apiece. But both shipment volume as well as profit margins sit somewhere between an iPhone and a GB200. The EV-components business is Foxconn’s for the taking, if it doesn’t screw up by trying to be a carmaker.

Foxconn’s future manufacturing plans in both product areas leads us to the next theme:

Centralized Production is Over. Regionalism is the Future.

Note Fact 3 above about Foxconn’s sprawl. Of course, the caveat to this “globalization” is that the vast majority of it is in China. But then there’s Fact 3, Foxconn’s building the world’s biggest AI server factory in Mexico. This facility, in addition to all the other stuff it’s doing South of the Border, still doesn’t get anywhere near the scale it currently has in China. But it doesn’t need to, the point is that a shrinking proportion of stuff is getting done in one place.

As far as the technology hardware sector is concerned, if we accept that personal gadget growth has peaked — by which I mean phones, consoles, TVs, PCs and notebooks — and that Big & Expensive tech will be the driver of semiconductor and electronic components for the next couple of decades, then there’s really no need to have all our production eggs in the China basket (or any basket, for that matter).

Cars lend themselves very well to localization. “Regional manufacturing is the direction,” Foxconn’s Liu said at HHTD. “Tariffs are just an advantage for us, not a disadvantage.”

Next to fresh produce, there are few items that are better sourced locally than automobiles. You can get almost anything made at a centralized factory surrounded by entire cities full of suppliers. Even more so when cheap sea and air freight can have these goods sent across the globe within days. But cars, given their size, price, weight and local-market preferences (you don’t see a lot of F100s in Tokyo) don’t benefit as much from all being made in one place.

Despite the rise of Asia’s car sector over the past 50 years, it’s still a highly decentralized and globally-distributed industry. And since more chips and modules will be going into cars than gadgets — and much of this will be specialty high-margin components — then the natural trend will be for electronics manufacturing to gradually decentralize, too.

Assembly of AI servers fit into the same theme, but a little differently. There’s no actual localization of the GB200, it’s the same product everywhere. And its high price makes the extra cost of air freight miniscule. Instead, the build-local push comes almost entirely from national security concerns. Policymakers feel far more comfortable having these products made next door than across the ocean in ‘hostile’ territory.

Nevertheless, companies like Foxconn, with their heft (See Fact 5: lots of injection molding capacity) ought to benefit most from these changes. However — and this is crucial to the global economic changes that are upon us — small, local and nimble new entrants will have every chance of breaking into the electronics supply chain since China-based incumbents will see their advantage diminished.

Which leads us to the next theme from Hon Hai Tech Day, and perhaps the one most pertinent to the shifting sands in the global economy:

Cheap-Labor Production is No Longer Cheaper. Nor Productive.

The obsession with generative-AI’s ability to write school essays and produce deep fake videos has taken attention away from far more powerful use-cases that are being developed. Multi-modal models — which are built across text, image, video and parametric information like temperature and air pressure — allow production to be customized quickly.

Instead of massive, single-item production runs which are necessary because tools and materials need to be set up and tuned, often manually, a new approach will be available. Small, mixed-batch manufacturing will be possible because AI-generated material recipes and tool settings will allow a machine to quickly switch from polishing the corners of an iPhone case to carving out the innards of a car door handle. Foxconn, for example, showed a de-burring machine that can smooth out the interior edges of a smartphone chassis in 45 seconds — multiples faster than a human currently does with manually-operated machinery.

Until now, what’s held back automation has been the lack of a few things: the ability for a machine to accurately assess its position in 3D space, its ability to position and move itself precisely enough for many of the tasks needed, and the time taken to set up and “train” the machine to actually do the job required. For example, drilling a hole may move the target item by a tiny amount but a machine needs to predict, sense and then calculate in real time how to fix the error.

Now, more advanced sensors coupled with artificial intelligence — where the system can assess, predict, and adjust on the fly — bring human-level accuracy and ‘feel’ to the most precise and unpredictable tasks. This machine-software duo boosts automation to a level which can render even the most menial human-operated tasks uncompetitive.

As a result, there’s little advantage in hiring armies of cheap labor in low-wage economies to do production runs which supply the entire planet. Instead, skilled well-paid technicians who are able to set up and monitor entire arrays of robots will be far more productive. And that makes supplying just the local market cost competitive.

Tech Change Trumps Trade War

When you put all these developments together, you can see that a lot of the changes wrought by the trade war between China and The West (led by the US) was likely to happen anyway.

China was becoming a victim of its own economic development even before then-President Donald Trump started ratcheting up trade tensions. Higher domestic wages, a slowing global economy, and the supply-side pump priming that the world’s second-largest economy now must reckon with were always going to happen no matter who’s in the White House. But national security concerns and a need to bring jobs back home has forced the US administration to sharpen its focus.

Foxconn — as the single-largest corporate trading partner of the United States — is neither the victim of these changes nor the cause. Instead, it’s a bellwether of the structural shift in international trade and economics. Where it goes, and what it does, will be the lodestar for global industry.

Policymakers and corporate chiefs would do well to pay attention.

Thanks for reading.

Wow💯🎯✔️☘️ really illuminating… I had no idea of FCs servers’ involvement or margins

Essential reading. Great job 👏